| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : HWASHI

Model Number : WL-SQ-150K*2

Certification : CE

Place of Origin : CHINA

MOQ : 1 set

Price : Negotiation

Payment Terms : L/C, T/T

Supply Ability : 50 sets per month

Delivery Time : 30 - 45 working days after received your payment

Packaging Details : Sea worthy wooden package or PVC Film for FCL

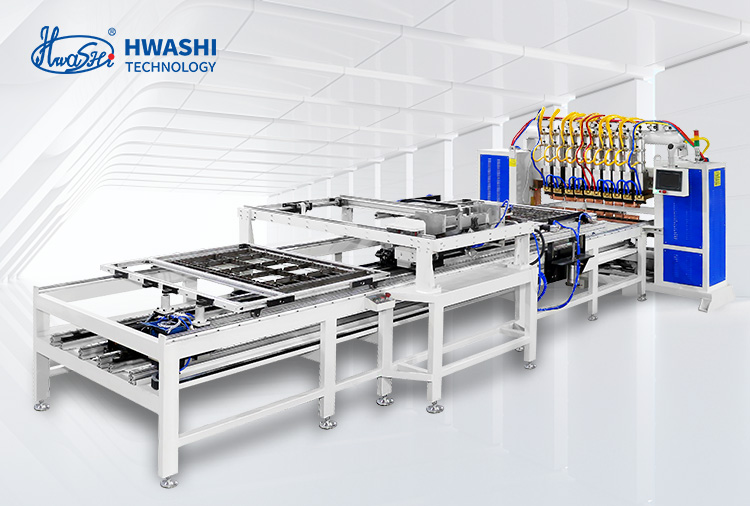

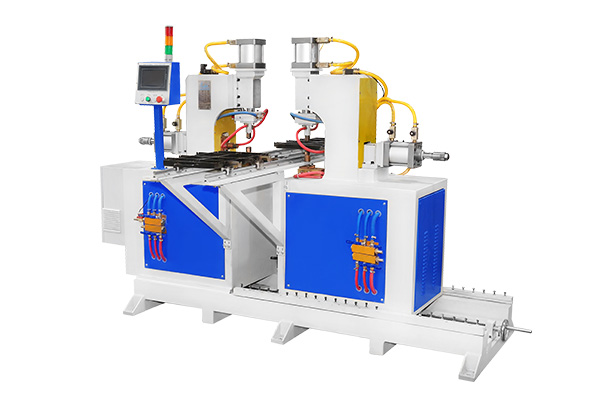

Product Name : Automatic Wire Mesh Spot Welding Machine with Wire Loading Lopper

Dimension(L*W*H) : According to your product

Weight : According to your product

Core Components : PLC, Engine, Motor

Warranty : 1 Year

Welding Power Source : AC / MF DC

Automatic Wire Mesh Spot Welding Machine with Wire Loading Lopper

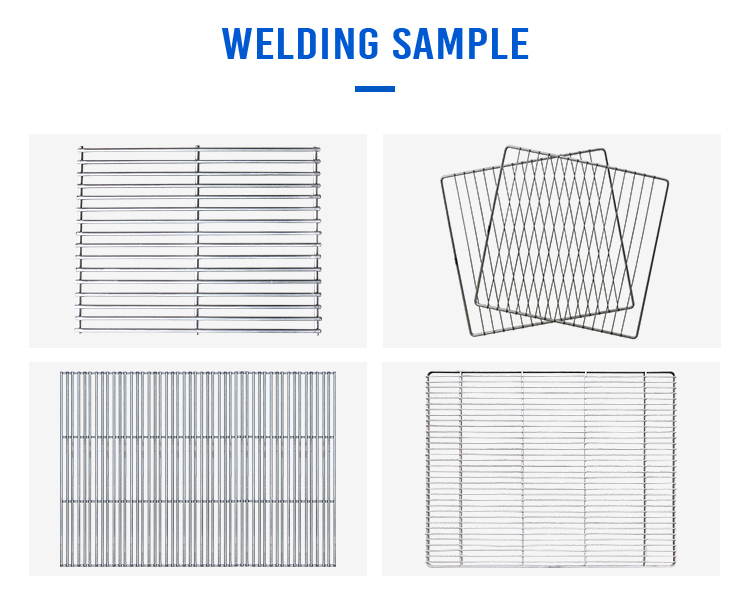

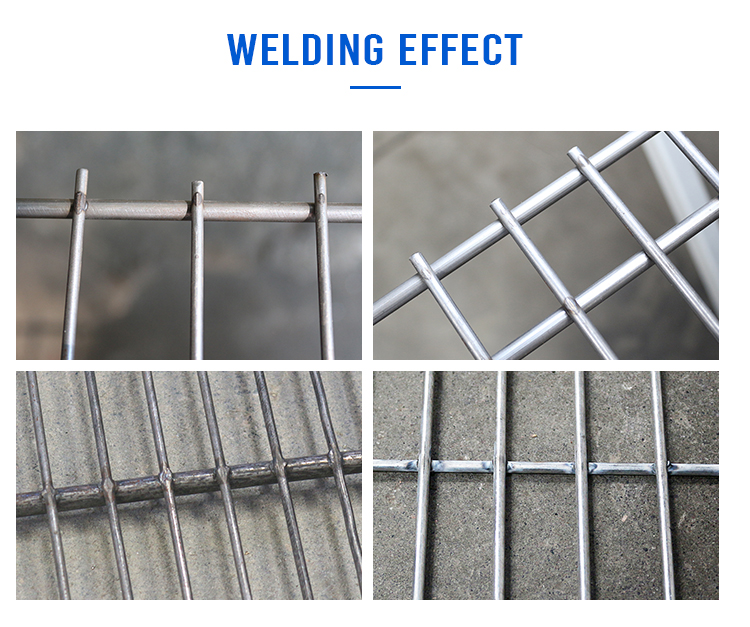

● Harnessing the power of intermediate frequency inverter DC square wave output, this welding system concentrates heat effectively and ensures symmetrical solder joints. Its specialty lies in adeptly handling non-ferrous metals and challenging-to-weld materials. The welding process is not only stable but significantly enhances welding quality, leading to a rapid boost in production efficiency. This equipment's versatility is further highlighted as it expands the range of applications it can handle.

● The compact welding transformer within the intermediate frequency inverter power supply boasts a small footprint while delivering substantial output energy. This reduction in the iron core material's weight is complemented by the rectifier diode in the secondary circuit, converting electric energy into a welding-friendly DC power supply. This design optimizes the secondary loop inductance, curbing energy losses and consequently lowering production costs.

● Embracing microcomputer control, this system excels in flexibility by storing multiple welding specifications. Users have the freedom to edit cylinder action sequences, determine the number of cylinder actions, and align them with specific welding specifications, facilitating the seamless welding of diverse products.

● The integral ultra-wide gantry frame is a testament to robust construction, crafted from high-quality steel. The lower beam, post-welding, undergoes annealing with 45# reinforcing ribs. This meticulous process ensures minimal elastic deformation, guaranteeing the absence of distortion in the entire structure during welding cylinder compression. The result is a stable framework that prevents product misalignment, eliminating potential issues arising from fuselage instability during welding.

|  |

Intelligent welding control system | Welding Heads and Fixtures |

|  |

Automatic Wire Filling System | Automatic Double-layer Feeder |

Production Line Machines

|  |

Wire Flattening and Cutting Machine | High Speed Wire Straightening and Cutting Machine |

|  |

Wire Frame Bending Machine | Wire Frame Butt Welding Machine |

|  |

Wire Frame Double T-Butt Machine | Wire Edge Trimming Machine |

|  |

2D Wire Handle Bending Machine | 3D Wire Bending Machine |

|

|

Automatic Wire Mesh Spot Welding Machine With Wire Loading Lopper Images |